Take advantage of the reliable and cost effective Metso Outotec Larox FP (Hoesch) filter press.

Metso Outotec® Larox FP Filter Press

Filter presses are designed for semi-automatic or fully automatic operation, and the filtration area reaches 1200 m 2 . The filters comply with the latest European quality standards and guarantee the safety of operators with perimeter protection and safety interlocks.

- Adaptability to changing process conditions

- Cycle time reduction due to membrane compression

- Uniform filter cake formation

- Less flushing liquid and faster cleaning

- Reducing energy consumption during cake drying

- High specific productivity due to reduced operation times

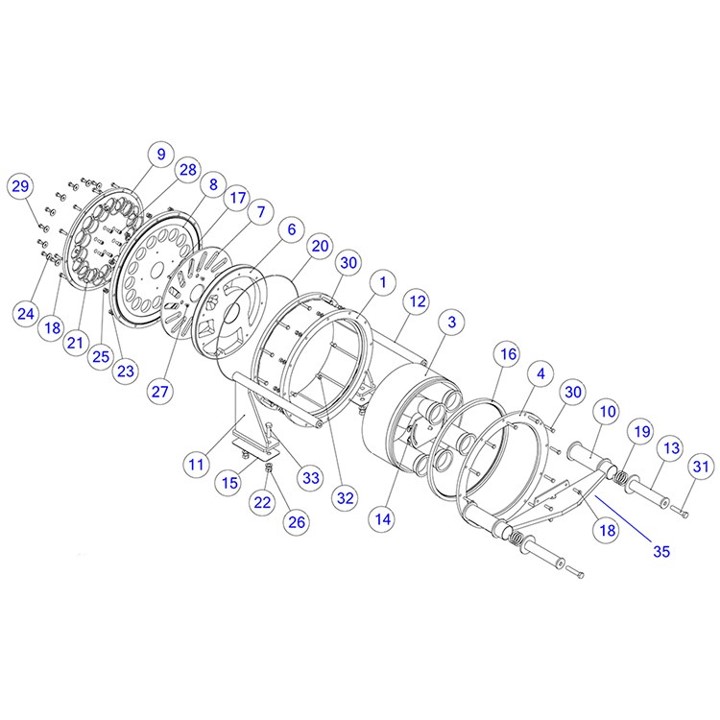

Metso Outotec filter presses are chamber or membrane press filters with vertical chambers. Filter plates have different areas and volumes of chambers. The line of equipment includes filters with a filtration area from 30 to 1200 m 2 or a volume from 2.1 to 25 m 3 .

The plate pack is opened and closed by hydraulic cylinders. In the closed position, the plates form airtight chambers with a filter cloth between them. When closing the package of plates, channels for supplying and distributing the pulp and collectors for removing the filtrate are formed. The slurry is pumped into all chambers simultaneously to form a cake on both sides of the plate. After the cake is formed, the membranes are filled with a pressing medium (water or air) to compress the cake and remove moisture from it. Each chamber has a rubber or polypropylene membrane. The slab package consists of alternating chamber and membrane slabs. The cake washing liquid is fed into the chambers through pulp or filtrate channels at subsequent stages of the process.

Drying air is supplied through filtrate channels. Upon completion of filtration, the cake is unloaded as the chambers are opened. The filter press can be adapted to specific operating conditions thanks to the modular design of the components and the choice of standard and optional equipment, such as equipment for unloading and transporting cakes, as well as a fabric cleaning system.

Metso Outotec filters are available with a semi-automatic or automatic control system for mechanical operation and process optimization. All operations are controlled through the filter's programmable logic controller. Additional equipment such as conveyors and other auxiliary equipment can be integrated into the control system. Metso Outotec offers comprehensive solutions, testing and maintenance to help you select the best filtration process solution; provides advice on plant design and guarantees efficient and reliable operation.

Service

Filtration experts will work closely with you to develop the most suitable service solution.

Get accurate information about the condition of your equipment, recommendations for maintenance and improvement of its operation.

Benefit from our extensive research and development package to support your business throughout.

Ensure compliance with your plant's maintenance and operations management requirements with dedicated .

Reduce your operating costs per ton and minimize downtime with optimal downtime.

Improve your service quality with the Metso Outotec Electronic Parts Catalog.